I-Ta-C Coating In Molding

Izicelo ze-ta-C coating ekubumbeni:

I-Tetrahedral amorphous carbon (ta-C) iyinto eguquguqukayo enezici ezihlukile eziyenza ifaneleke kakhulu ukusetshenziswa okuhlukahlukene ekubumbeni. Ukuqina kwayo okungavamile, ukumelana nokuguga, i-coefficient ephansi yokungqubuzana, kanye nokungangenisi kwamakhemikhali kunomthelela ekusebenzeni okuthuthukisiwe, ukuqina, nokuthembeka kwesikhunta nemikhiqizo ebunjiwe.

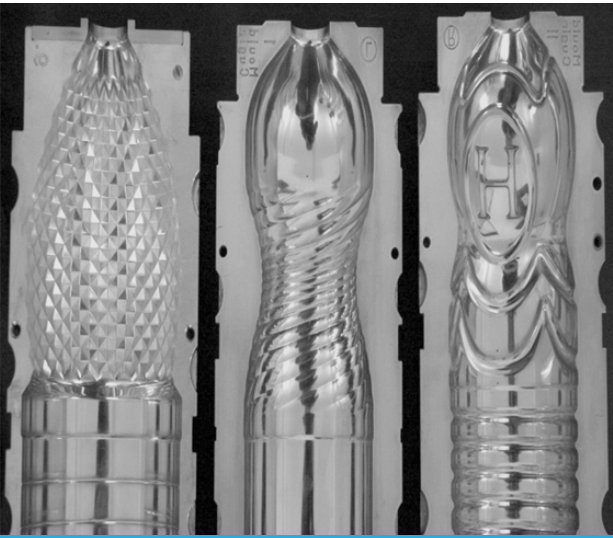

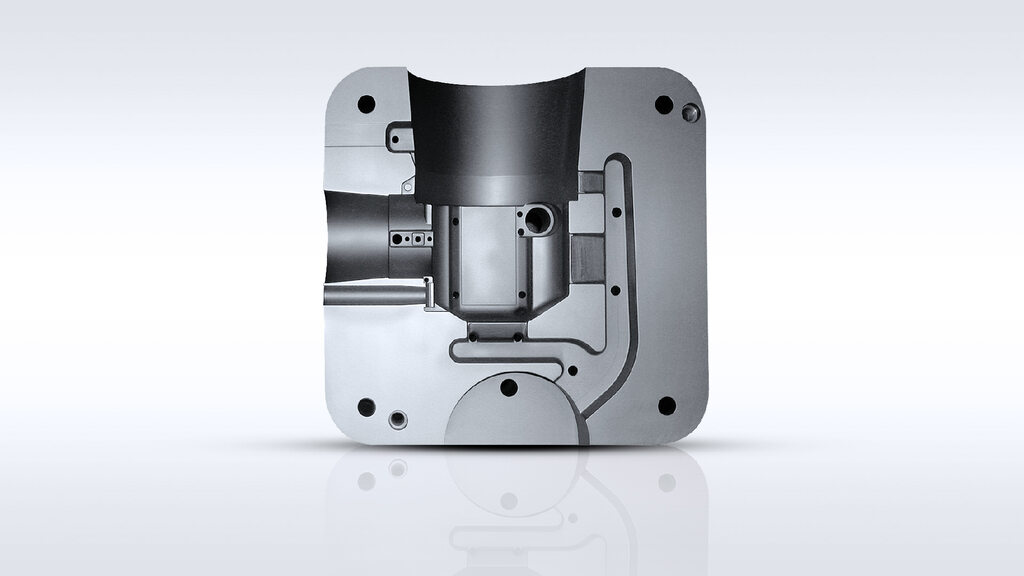

I-1.I-injection molding: I-ta-C yokugqoka isetshenziswa emigodini yesikhunta yomjovo ukuze kuthuthukiswe ukumelana nokugqoka nokunciphisa ukungqubuzana ngesikhathi sokujova kanye nenqubo yokukhipha. Lokhu kwandisa isikhathi sokuphila sesikhunta futhi kuthuthukisa izinga eliphezulu lezingxenye ezibunjiwe.

2.I-Die casting: Izingubo ze-ta-C zisetshenziswa ku-die casting dies ukuze zivikeleke ekugugeni nasekuhuhukeni okubangelwa ukugeleza kwensimbi encibilikisiwe. Lokhu kuthuthukisa ukuqina kokufa futhi kunciphisa ukukhubazeka kokukhipha.

I-3.Ukubunjwa kwe-Extrusion: I-ta-C yokugqoka isetshenziselwa ukufa kwe-extrusion ukuze kuncishiswe ukungqubuzana nokugqoka ngesikhathi senqubo ye-extrusion. Lokhu kuthuthukisa isiphetho esingaphezulu semikhiqizo ekhishwe futhi kunciphisa ukunamathela kokufa.

I-4.Ukubunjwa kwe-Rubber: I-ta-C yokugqoka isetshenziswa ekubunjweni kwenjoloba ukuze kuthuthukiswe ukukhululwa nokuvimbela ukunamathela kwezingxenye zenjoloba endaweni yokubunjwa. Lokhu kuqinisekisa ukudilizwa okubushelelezi futhi kunciphisa amaphutha.

I-5.I-Glass molding: I-ta-C yokugqoka isetshenziselwa isikhunta sokubumba ingilazi ukuze kuvikelwe ekugugeni nasekuhusheni ngesikhathi sokubumba. Lokhu kwandisa isikhathi sokuphila sesikhunta futhi kuthuthukisa izinga eliphezulu lemikhiqizo yengilazi.

Sekukonke, ubuchwepheshe bokumboza i-ta-C budlala indima ebalulekile ekuthuthukisweni kwezinqubo zokubumba, bubambe iqhaza ekuthuthukisweni kwekhwalithi yomkhiqizo, ukunciphisa izindleko zokukhiqiza, nokuphila kwesikhunta okwandisiwe.