Ta-C Coating in Molding

Usetyenziso lwe-ta-C yokwambathisa ekubumbeni:

I-Tetrahedral amorphous carbon (ta-C) yimpahla eguquguqukayo eneempawu ezizodwa ezenza ukuba ifaneleke kakhulu kwizicelo ezahlukeneyo ekubumbeni. Ukuqina kwayo okungaqhelekanga, ukumelana nokunxiba, ukukhuhlana okuphantsi, kunye nokungangeni kweekhemikhali kunegalelo ekuphuculweni kokusebenza, ukuqina, kunye nokuthembeka kokubumba kunye neemveliso ezibunjiweyo.

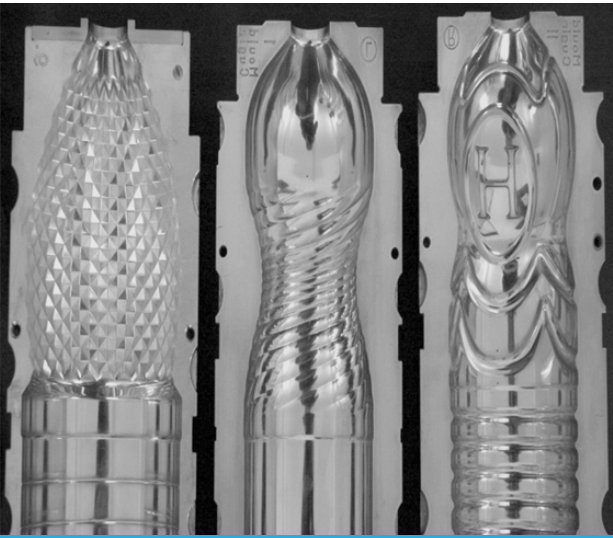

I-1.Injection molding: Iingubo ze-ta-C zifakwe kwi-injection mold cavities ukuphucula ukuxhathisa ukunxiba kunye nokunciphisa ukungqubuzana ngexesha lokutofa kunye nenkqubo yokukhupha. Oku kwandisa ubomi bokubumba kunye nokuphucula umgangatho womgangatho weendawo ezibunjiweyo.

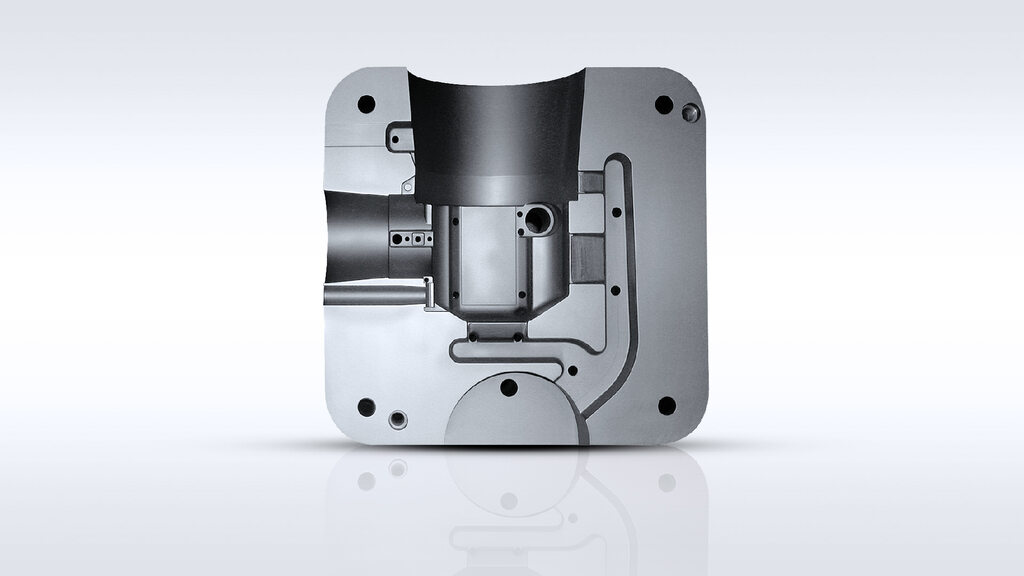

2.I-Die casting: I-ta-C yokugquma isetyenziswa kwi-die casting dies ukukhusela ekugugeni kunye nokukrazuka okubangelwa kukuhamba kwesinyithi esinyibilikisiweyo. Oku kwandisa ukuqina kokufa kunye nokunciphisa iziphene zokuphosa.

I-3.Ukubunjwa kwe-Extrusion: iingubo ze-ta-C zifakwe kwi-extrusion dies ukunciphisa ukukhuhla kunye nokunxiba ngexesha lenkqubo yokukhupha. Oku kuphucula ukugqitywa komphezulu weemveliso ezikhutshiweyo kwaye kunciphisa izinto ezincamathelayo kwiifa.

I-4.I-Rubber yokubunjwa: iingubo ze-ta-C zisetyenziselwa ukubumba i-rubber yokubumba ukuphucula ukukhululwa kunye nokuthintela ukunamathela kwiindawo zerabha kwindawo yokubumba. Oku kuqinisekisa ukubunjwa okugudileyo kunye nokunciphisa iziphene.

I-5.I-Glass Molding: Iingubo ze-ta-C zisetyenziselwa ukubumba i-glass molds ukukhusela ukuguga kunye ne-abrasion ngexesha lokubumba. Oku kwandisa ubomi bomngundo kwaye kuphucule umgangatho womphezulu weemveliso zeglasi.

Lilonke, itekhnoloji yokugquma i-ta-C idlala indima ebalulekileyo ekuqhubeleni phambili kweenkqubo zokubumba, igalelo kuphuculo lomgangatho wemveliso, ukunciphisa iindleko zemveliso, kunye nobomi obandisiweyo bokubumba.