Ta-C Coating In Molding

Mashandisirwo eta-C coating mukuumbwa:

Tetrahedral amorphous kabhoni (ta-C) chinhu chakasiyana-siyana chine zvimiro zvakasarudzika chinoita kuti chinyatsokodzera kushandiswa kwakasiyana-siyana mukuumbwa. Kuomarara kwayo kwakasarudzika, kusamira kwekusapfeka, kuderera kwekukweshana, uye kusagadzikana kwemakemikari zvinobatsira mukusimudzira mashandiro, kusimba, uye kuvimbika kwe mold uye zvigadzirwa zvakaumbwa.

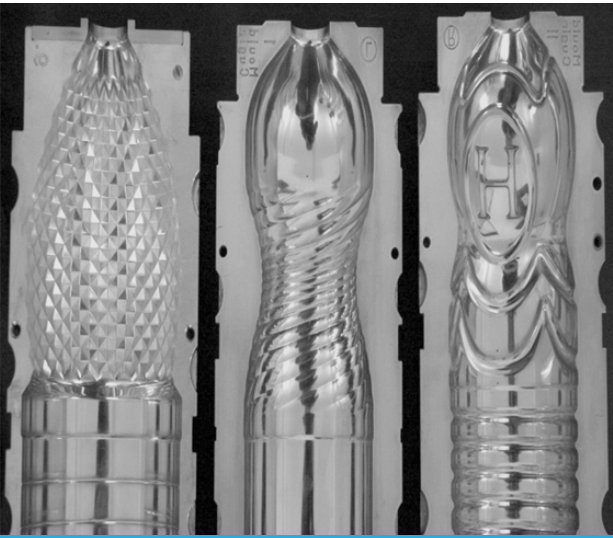

1.Injection molding: ta-C coatings inoshandiswa kune jekiseni mold cavities kuti ivandudze kupfeka kusagadzikana uye kuderedza kupesana panguva yejojo uye ejection process. Izvi zvinowedzera hupenyu hwema molds uye inovandudza kunaka kwepamusoro pezvikamu zvakaumbwa.

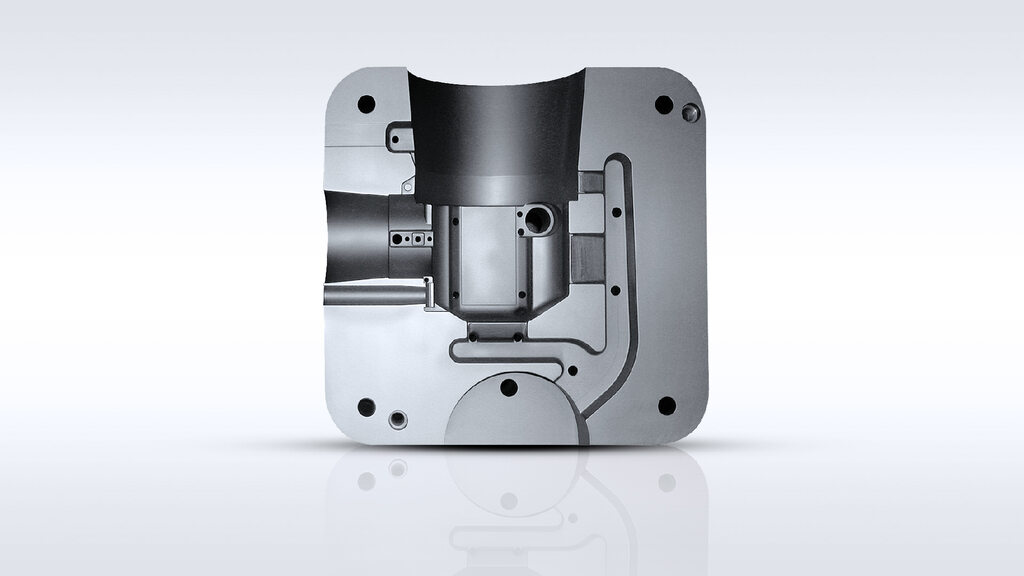

2.Die casting: ta-C coatings inoshandiswa mukufa casting dies kudzivirira kubva pakusakara uye abrasion kunokonzerwa nekuyerera kwesimbi yakanyungudutswa. Izvi zvinowedzera kusimba kwekufa uye kuderedza kukanganisa kwekukanda.

3.Extrusion molding: ta-C coatings inoshandiswa kune extrusion inofa kuderedza kukakavara uye kupfeka panguva ye extrusion process. Izvi zvinonatsiridza kupera kwepamusoro kwezvigadzirwa zvakaburitswa uye zvinoderedza zvinhu zvinonamatira kune inofa.

4.Rubber molding: ta-C machira anoshandiswa mukugadzira rubber molds kuti avandudze kusunungurwa uye kudzivirira kunamatira zvikamu zverubha kune mold pamusoro. Izvi zvinogonesa kudhirowa kwakanaka uye kunoderedza kuremara.

5.Glass molding: ta-C machira anoshandiswa kune magirazi ekuumba molds kudzivirira kubva pakupfeka uye abrasion panguva yekuumba. Izvi zvinowedzera hupenyu hwema mold uye inovandudza kunaka kwepamusoro pezvigadzirwa zvegirazi.

Pakazere, ta-C yekubikira tekinoroji inoita basa rakakosha mukufambisira mberi kwemaitiro ekuumba, zvichibatsira mukuvandudzwa kwemhando yechigadzirwa, kuderedzwa kwemitengo yekugadzira, uye nekuwedzera hupenyu hwekuumbwa.