TB900X8Ω HF Driver - 1.4 inches

Performance:

● 220W continuous power capacity

● 1.4 " diameter CNC precision machined aluminum horn throat

● 75 mm (3 in ) ta-C diamond carbon fiber composite diaphragm

● N38H high performance NdFeB magnet assembly with shorting copper cap

● Frequency range: 500Hz-20,000Hz ( ± 3dB )

● Maximum sound pressure: 135dB@1m

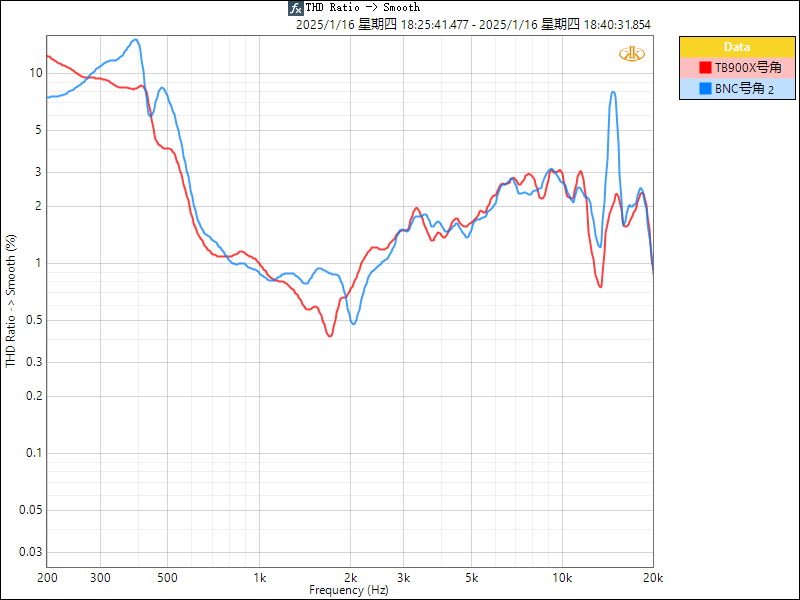

● Harmonic distortion: < 0.5%@1kHz

● Sensitivity: 108.5 dB

Unique advantages:

● 12 exclusive processes: from ultra-fine carbon fiber weaving to diamond molecule deposition, zero-tolerance quality control throughout the entire process !

● Data crushing: diaphragm hardness/damping/rigidity in three dimensions surpass traditional metal units !

● Acoustic supremacy: The world's first tweeter driver to achieve "zero-division vibration"!

● Applicable fields: million-level Hi-End speakers/ten thousand-person stadium accoustic system/aerospace-level monitoring system !

TB900X8Ω HF Driver - 1.4 inches

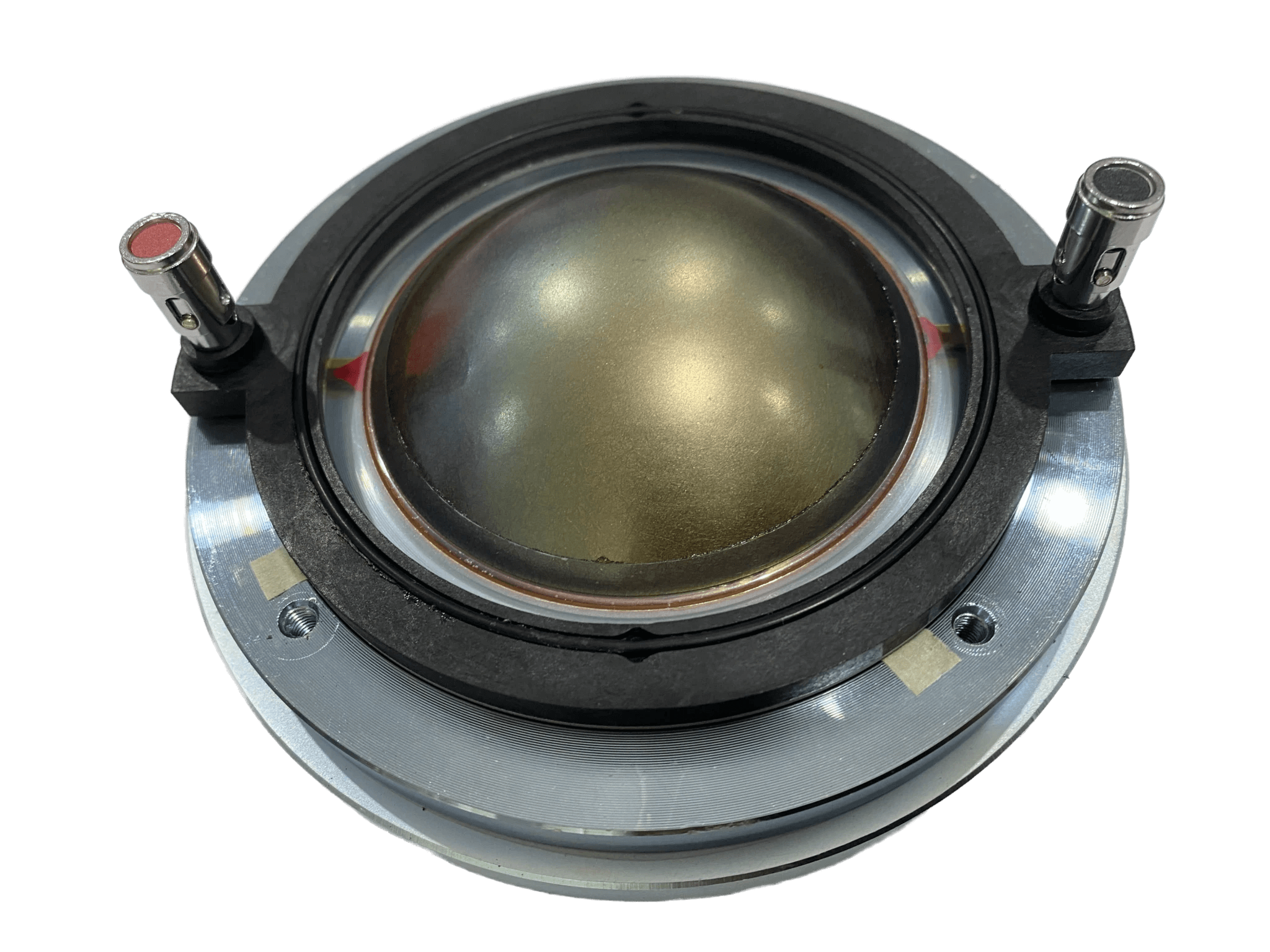

Core technology: diamond carbon fiber composite diaphragm

Using " nano-penetration coating cutting-edge technology " , diamond molecules are allowed to penetrate into every gap of carbon fiber like " liquid " , and through high-energy particle bombardment, the molecules are bonded, and the multi-layer carbon fiber substrate and diamond coating are melted into a " seamless monomer structure " ! So it's not plating, it's rebirth.

● " Three-dimensional steel skeleton " :

Internal carbon fiber mesh skeleton + surface 2μm diamond armor, rigidity increased by 400% .

● " Hardness and Softness " :

Mohs hardness 10 + damping coefficient 0.25 , residual vibration attenuation speed reaches 0.8ms (traditional diaphragm 5ms ), Completely eliminate the " metallic taste " ;

● " Acoustic Zero Loss " :

One-piece molding eliminates 99% of interface reflections, and the high-frequency purity is comparable to that of an electrostatic unit!

Each diaphragm undergoes 36 hours of supercritical process + 3D-CT inspection.

TB900X8Ω HF Driver - 1.4 inches

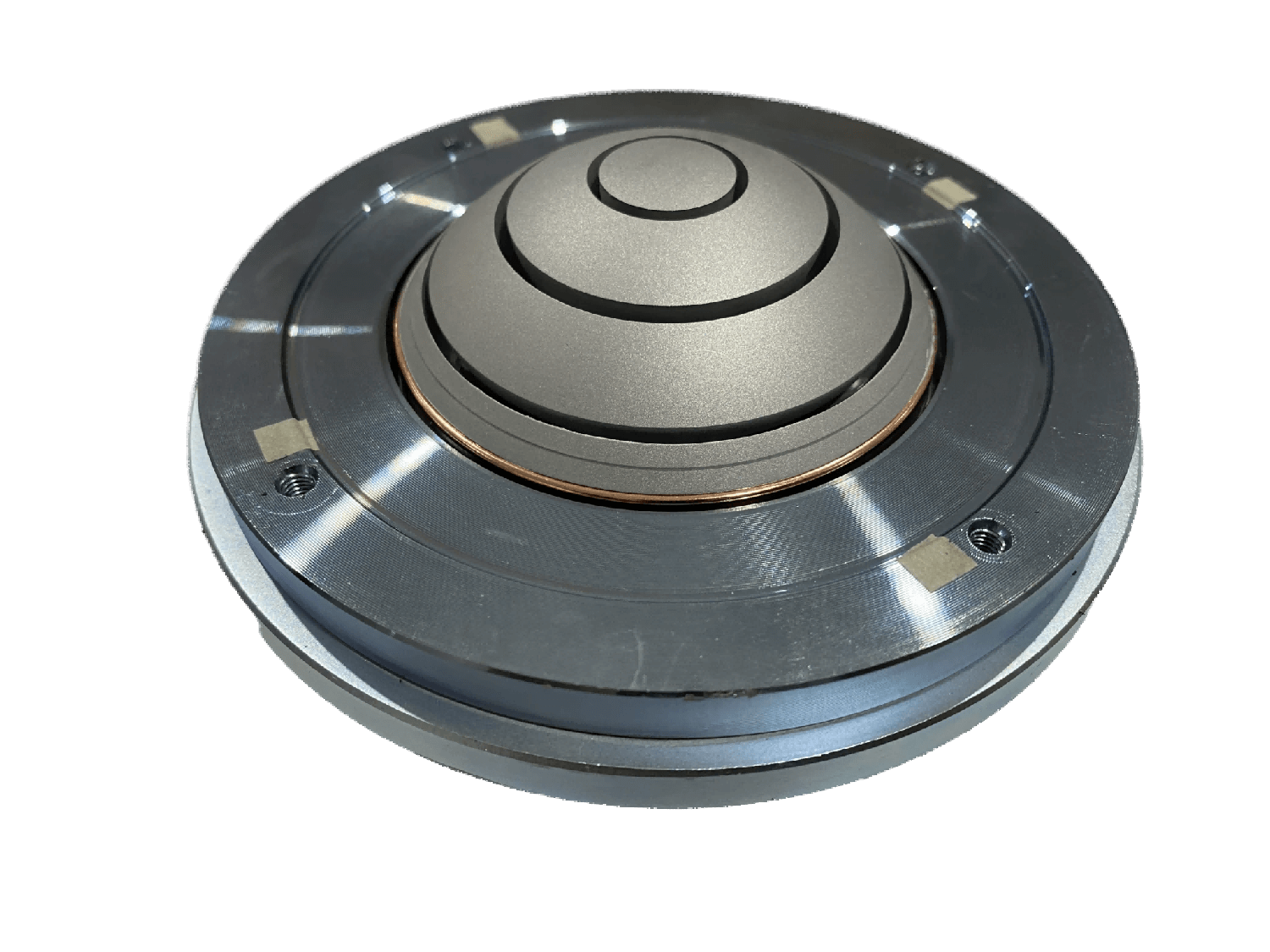

CNC precision machining of aerospace aluminum phase plug

● CNC Aerospace Aluminum Phase Plug:

0.005mm precision acoustic wave guide, diffusion angle accurate to ± 1 ° ;

● 1.4" Compression Throat:

98% sound energy conversion efficiency and 108.5dB sensitivity shake the whole audience!

● N38H NdFeB megnet:

1.8 Tesla magnetic flux density, driving force increased by 200% , transient response 0.03ms ;

● 75mm Copper Clad Aluminum voice coil

220W continuous power to withstand extreme sound pressure, 1000 hours of violent testing,rock-solid;

TB900X8Ω HF Driver - 1.4 inches

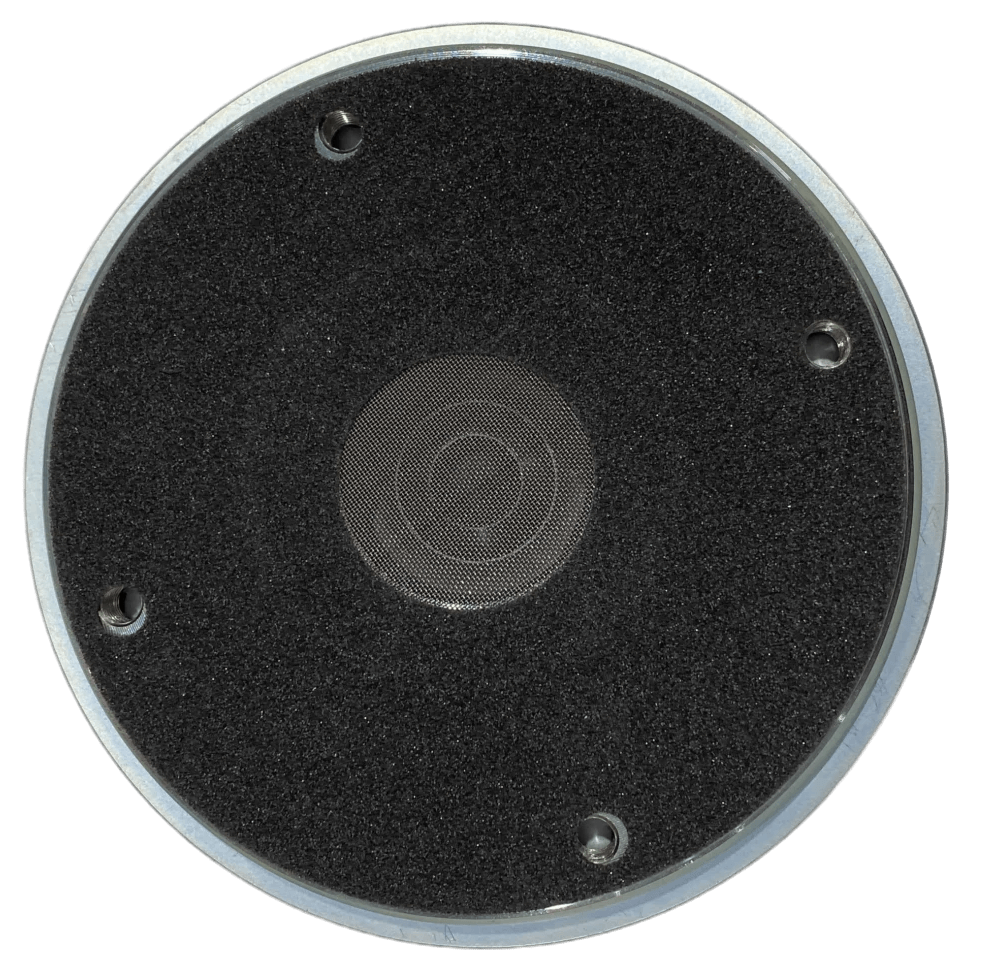

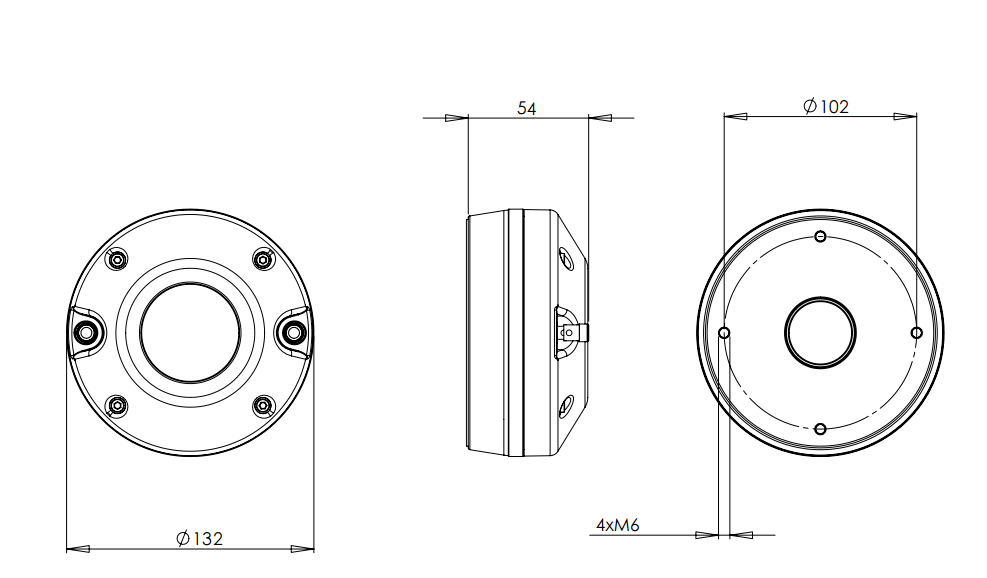

| Installation and transportation information

102 mm ( 4 in) diameter on 4 90 ° M6 holes |

|

| Additional details | 4 x M6 screw hole with bolts and nuts |

| Overall diameter | 132 mm ( 5.2 in) |

| high | 54 mm ( 2.1 in) |

| net weight | 2.35 kg ( 5.18 lbs) |

| unit | individual |

| Packing weight | 2.45 kg ( 5.4 lbs) |

| Packing volumn | 200×200×75 mm |

|

Technical Parameters |

|

| Throat diameter | 36 mm |

| impedance | 8Ω |

| Minimum impedance | 7.8Ω |

| Rated Power | 110W |

| Continuous processing power | 220W |

| Sensitivity | 108.5 dB |

| Frequency range | 0.5 KHz-20 KHz |

| Recommended crossover | 1.2 KHz |

| Voice coil diameter | 75 mm |

| Voice coil wire | Copper Clad Aluminum |

| inductance | 0.14mH |

| Diaphragm material | ta-C diamond carbon fiber composite diaphragm |

| Magnetic flux density | 1.8T |

| Maximum frequency range | 20 KHz |

| Minimum frequency range | 500 Hz |

TB900X8Ω HF Driver - 1.4 inches

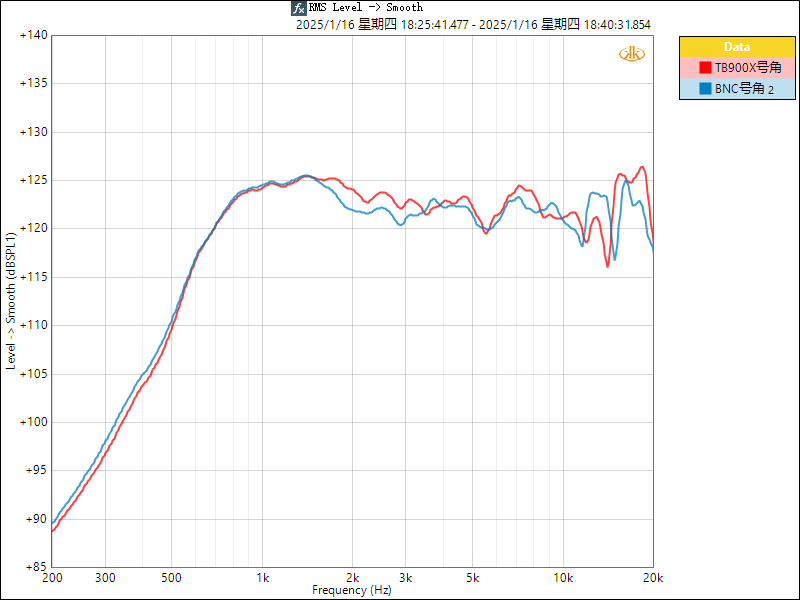

Audiobus TB900X

VS

B&C DE900

TB900X8Ω HF Driver - 1.4 inches

Professional evaluation:

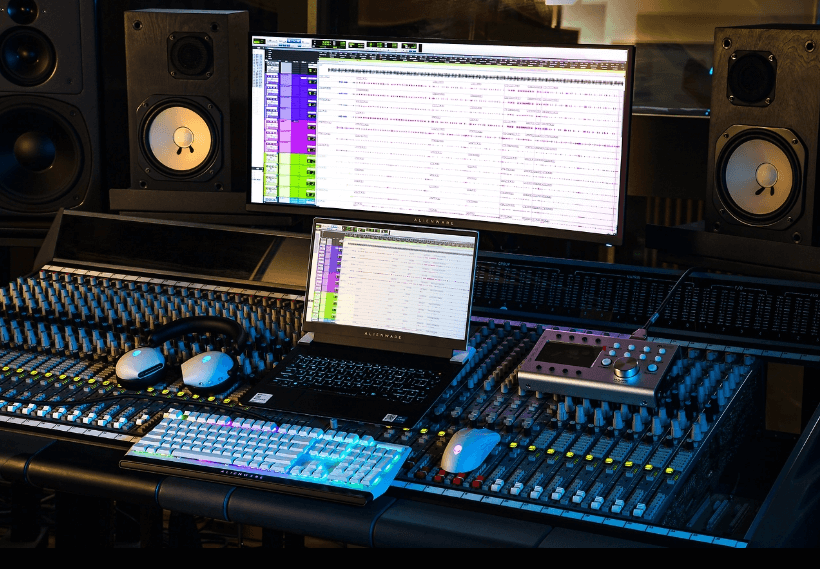

● sound engineer:

" It brings out the details buried in the master tape, like listening to the uncompressed original universe! "

● Audiophiles:

" The high notes are like melting iceberg water passing through the eardrum, sharp but without a single burr! "

● engineer:

" There were 100,000 people at the scene, and the vibrations of the ceiling cymbals seemed to explode in my ears! "