Mkpuchi Ta-C Na ịkpụzi

Ngwa nke mkpuchi ta-C na ịkpụzi:

Tetrahedral amorphous carbon (ta-C) bụ ihe dị iche iche nwere ihe pụrụ iche na-eme ka ọ dị mma maka ngwa dị iche iche na ịkpụzi. Isi ike ya pụrụ iche, nguzogide iyi, ọnụ ọgụgụ esemokwu dị ala, yana inertness kemịkalụ na-enye aka n'ịkwalite arụmọrụ, ịdịte aka, na ntụkwasị obi nke ebu na ngwaahịa a kpụrụ akpụ.

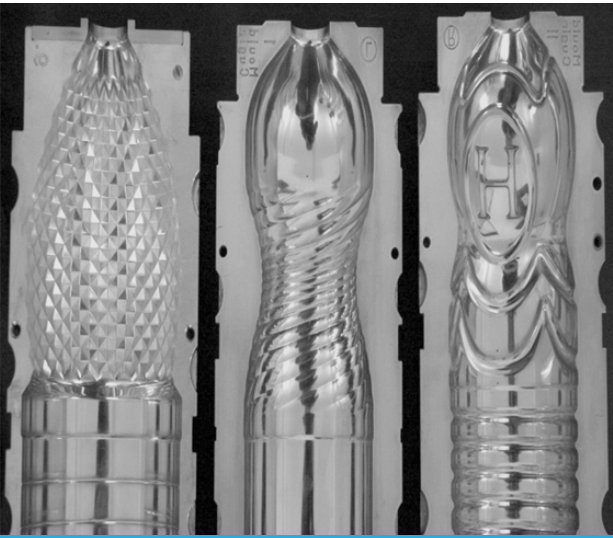

1.Injection ịkpụzi: ta-C mkpuchi na-etinyere na injection ebu cavities iji melite eyi iguzogide ma belata esemokwu n'oge injection na ejection usoro. Nke a na-agbatị ndụ nke ebu ma na-eme ka ọdịdị elu nke akụkụ ndị a kpụrụ akpụ dịkwuo mma.

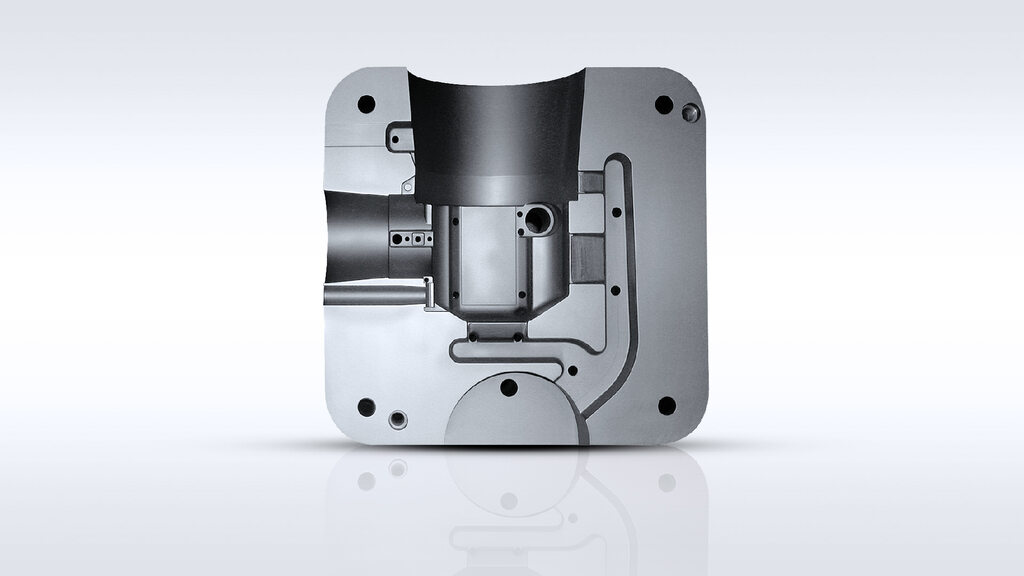

2.Die casting: A na-eji mkpuchi ta-C arụ ọrụ na nkedo anwụ anwụ iji chebe onwe ya pụọ na iyi na abrasion nke igwe gbazere agbaze kpatara. Nke a na-akwalite ịdịte aka nke ọnwụ ma na-ebelata ntụpọ nkedo.

3.Extrusion ịkpụzi: ta-C mkpuchi na-etinye aka na extrusion nwụrụ iji belata esemokwu na iyi n'oge extrusion usoro. Nke a na-eme ka njedebe elu nke ngwaahịa extruded dịkwuo mma ma belata ihe na-arapara n'ahụ anwụ.

4.Rubber ịkpụzi: ta-C mkpuchi na-eji na roba ịkpụzi ebu iji melite ntọhapụ na-egbochi ịrapara nke roba akụkụ na ebu elu. Nke a na-eme ka ọ dị nro ma na-ebelata ntụpọ.

5.Glass ịkpụzi: ta-C mkpuchi na-etinyere na iko ịkpụzi ebu iji chebe megide iyi na abrasion n'oge ịkpụzi usoro. Nke a na-agbatị ndụ nke ebu ma na-eme ka ọdịdị elu nke ngwaahịa iko dịkwuo mma.

N'ozuzu, teknụzụ mkpuchi ta-C na-ekere òkè dị ukwuu na ọganihu nke usoro ịkpụzi, na-enye aka n'ịdị mma ngwaahịa, belata ụgwọ ọrụ mmepụta ihe, na ogologo ndụ ịkpụzi.