Ta-C txheej hauv Moulding

Kev siv ta-C txheej hauv molding:

Tetrahedral amorphous carbon (ta-C) yog cov khoom siv ntau yam nrog cov khoom tshwj xeeb uas ua rau nws tsim nyog rau ntau yam kev siv hauv molding. Nws tshwj xeeb hardness, hnav tsis kam, tsis tshua muaj kev sib txhuam coefficient, thiab tshuaj inertness pab txhawb kev ua tau zoo, durability, thiab kev ntseeg siab ntawm cov pwm thiab cov khoom pwm.

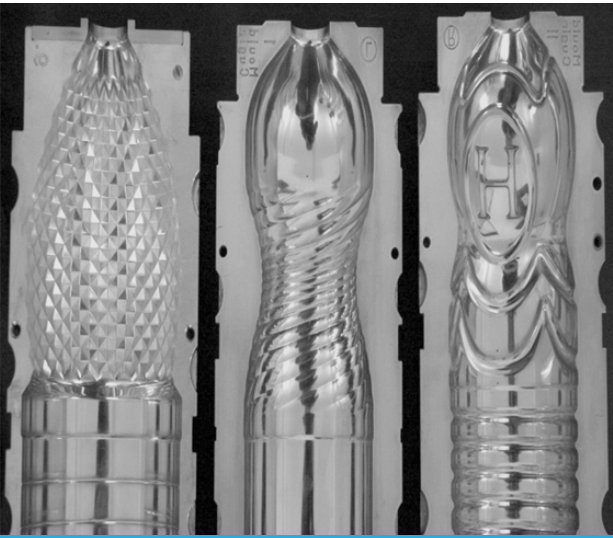

1.Kev txhaj tshuaj molding: ta-C coatings yog siv rau kev txhaj tshuaj pwm kab noj hniav kom txhim kho hnav tsis kam thiab txo kev sib txhuam thaum lub sij hawm txhaj tshuaj thiab ejection txheej txheem. Qhov no ua rau lub neej ntev ntawm cov pwm thiab txhim kho qhov zoo ntawm cov pwm pwm.

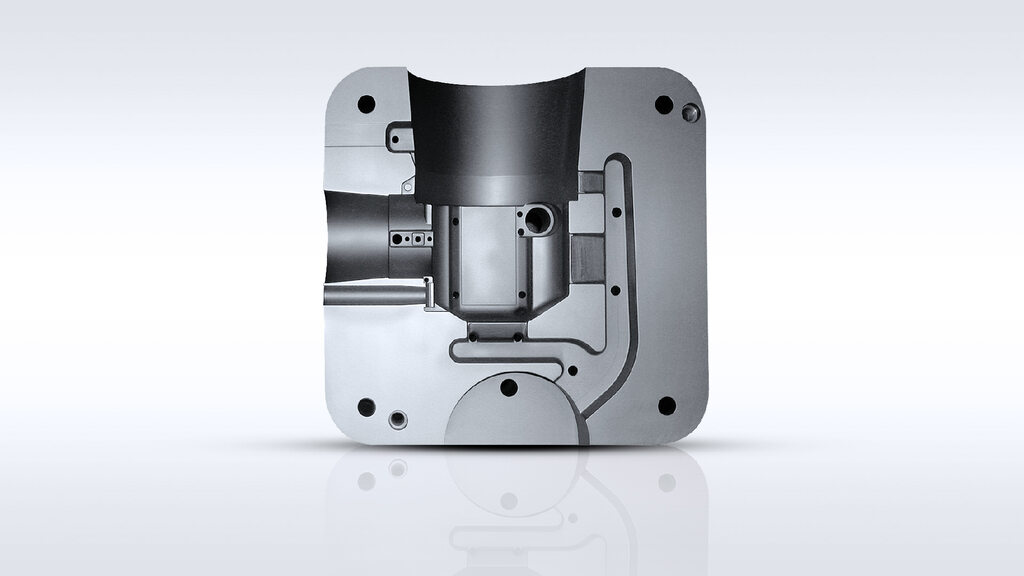

2. Tuag casting: ta-C coatings yog ua hauj lwm nyob rau hauv tuag casting tuag los tiv thaiv hnav thiab puas los ntawm cov hlau molten. Qhov no txhim khu lub durability ntawm tuag thiab txo qhov tsis xws luag casting.

3.Extrusion molding: ta-C coatings yog siv rau extrusion tuag kom txo kev sib txhuam thiab hnav thaum lub sij hawm extrusion txheej txheem. Qhov no txhim kho qhov chaw tiav ntawm cov khoom extruded thiab txo cov khoom ua rau cov tuag.

4.Rubber molding: ta-C coatings yog siv rau hauv cov roj hmab moulding pwm los txhim kho kev tso tawm thiab tiv thaiv kom tsis txhob lo rau ntawm cov khoom siv roj hmab rau cov pwm saum npoo. Qhov no ua kom du demolding thiab txo qhov tsis xws luag.

5.Glass molding: ta-C coatings yog siv rau iav molding pwm los tiv thaiv kev hnav thiab puas thaum lub sij hawm molding txheej txheem. Qhov no txuas ntxiv lub neej ntawm cov pwm thiab txhim kho qhov zoo ntawm cov khoom iav.

Zuag qhia tag nrho, ta-C txheej thev naus laus zis ua lub luag haujlwm tseem ceeb hauv kev nce qib ntawm cov txheej txheem molding, pab txhim kho cov khoom zoo, txo cov nqi tsim khoom, thiab txuas ntxiv lub neej pwm.