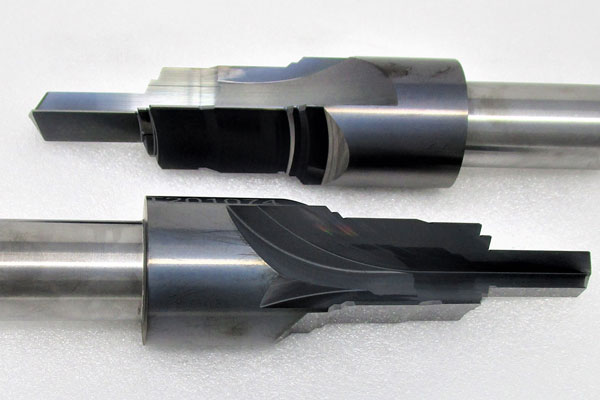

Ta-C Coating On Cutting Tools

Specific benefits of using ta-C coating on cutting tools:

Ta-C coating is used on cutting tools to improve their wear resistance, hardness, and toughness. This extends the tool life and improves the surface finish of the workpiece. Ta-C coatings are also used to reduce friction and heat generation, which can further improve the performance of cutting tools.

● Increased wear resistance: Ta-C coatings are extremely hard and wear-resistant, which can help to protect cutting tools from wear and tear. This can extend the tool life by up to 10 times.

● Improved hardness: Ta-C coatings are also very hard, which can help to improve the cutting performance of tools. This can lead to better surface finishes and reduced cutting forces.

● Increased toughness: Ta-C coatings are also tough, which means that they can withstand impact and shock loading. This can help to prevent tools from breaking or chipping.

● Reduced friction: Ta-C coatings have a low friction coefficient, which can help to reduce friction and heat generation during cutting. This can improve the performance of the tool and reduce wear on the workpiece.

Ta-C coated cutting tools are used in a wide variety of applications, including:

● Milling: Ta-C coated milling tools are used to machine a variety of materials, including steel, aluminum, and titanium.

● Turning: Ta-C coated turning tools are used to machine cylindrical parts, such as shafts and bearings.

● Drilling: Ta-C coated drilling tools are used to drill holes in a variety of materials.

● Reaming: Ta-C coated reaming tools are used to finish holes to a precise size and tolerance.

Ta-C coating is a valuable technology that can improve the performance and lifespan of cutting tools. This technology is used in a wide variety of applications and is becoming increasingly popular as the benefits of ta-C coatings become more widely known.