Ta-C Coating In Molding

Applications of ta-C coating in molding:

Tetrahedral amorphous carbon (ta-C) is a versatile material with unique properties that make it highly suitable for various applications in molding. Its exceptional hardness, wear resistance, low friction coefficient, and chemical inertness contribute to enhanced performance, durability, and reliability of molds and molded products.

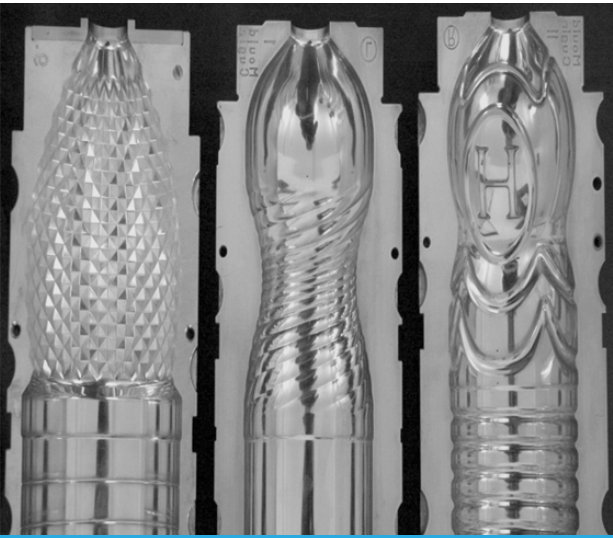

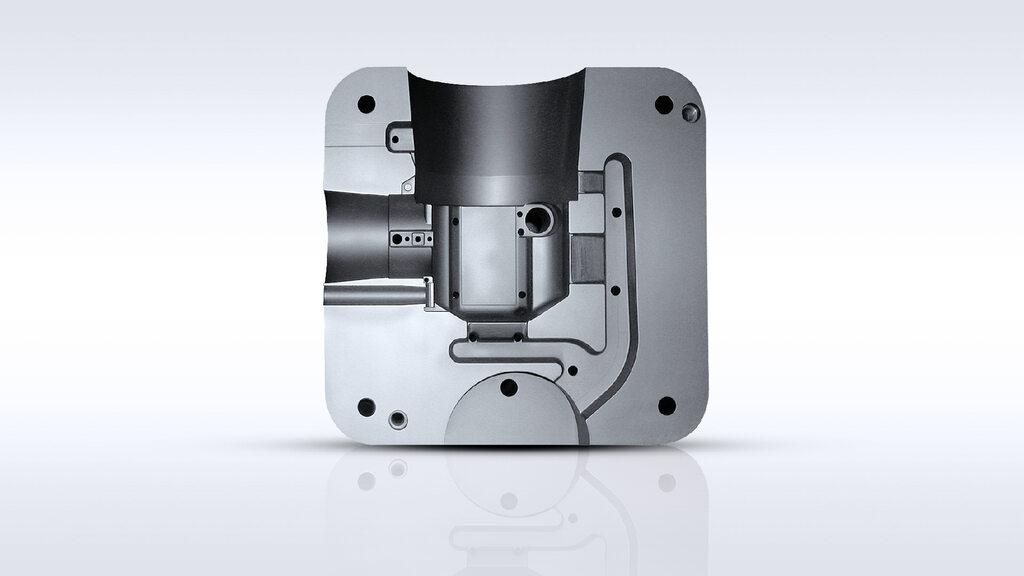

1.Injection molding: ta-C coatings are applied to injection mold cavities to improve wear resistance and reduce friction during the injection and ejection process. This extends the lifespan of molds and improves the surface quality of molded parts.

2.Die casting: ta-C coatings are employed in die casting dies to protect against wear and abrasion caused by the molten metal flow. This enhances the durability of dies and reduces casting defects.

3.Extrusion molding: ta-C coatings are applied to extrusion dies to reduce friction and wear during the extrusion process. This improves the surface finish of extruded products and reduces material sticking to the dies.

4.Rubber molding: ta-C coatings are used in rubber molding molds to improve release and prevent sticking of rubber parts to the mold surface. This ensures smooth demolding and reduces defects.

5.Glass molding: ta-C coatings are applied to glass molding molds to protect against wear and abrasion during the molding process. This extends the lifespan of molds and improves the surface quality of glass products.

Overall, ta-C coating technology plays a significant role in the advancement of molding processes, contributing to improved product quality, reduced production costs, and extended mold life.