Ta-C Coating In Electronic Devices

Applications of ta-C coating in electronic devices:

Tetrahedral amorphous carbon (ta-C) coating is a versatile material with unique properties that make it highly suitable for various applications in electronic devices. Its exceptional hardness, wear resistance, low friction coefficient, and high thermal conductivity contribute to enhanced performance, durability, and reliability of electronic components.

1.Hard Disk Drives (HDDs): ta-C coatings are widely used to protect the read/write heads in HDDs from wear and abrasion caused by repeated contact with the spinning disk. This extends the lifespan of HDDs and reduces data loss.

2.Microelectromechanical Systems (MEMS): ta-C coatings are employed in MEMS devices due to their low friction coefficient and wear resistance. This ensures smooth operation and prolongs the life of MEMS components, such as accelerometers, gyroscopes, and pressure sensors.

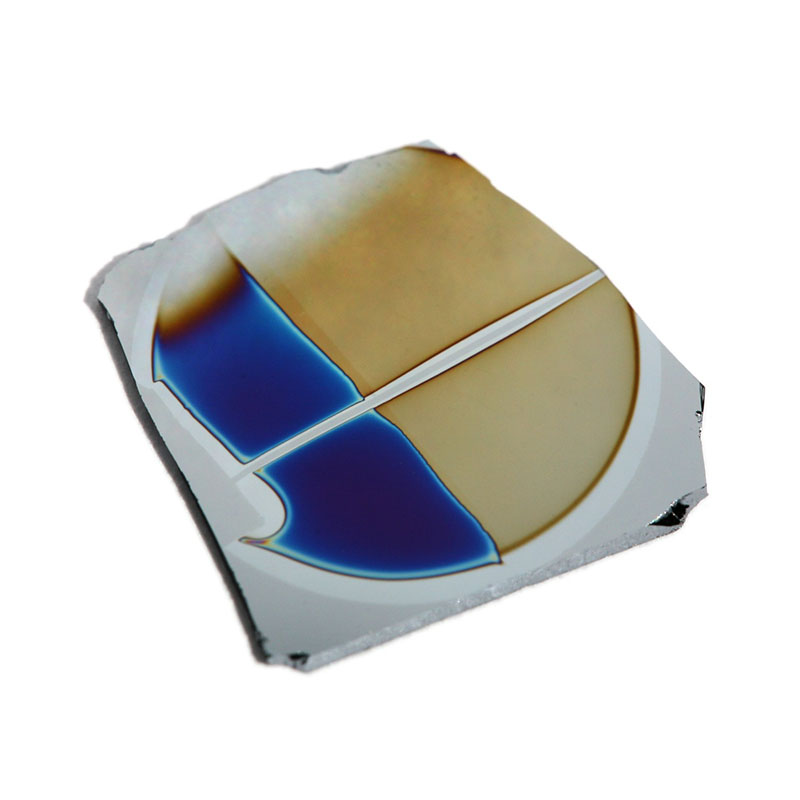

3.Semiconductor Devices: ta-C coatings are applied to semiconductor devices, such as transistors and integrated circuits, to enhance their heat dissipation capabilities. This improves the overall thermal management of electronic components, preventing overheating and ensuring stable operation.

4.Electronic Connectors: ta-C coatings are used on electronic connectors to reduce friction and wear, minimizing contact resistance and ensuring reliable electrical connections.

5.Protective Coatings: ta-C coatings are employed as protective layers on various electronic components to shield them from corrosion, oxidation, and harsh environmental conditions. This enhances the durability and reliability of electronic devices.

6.Electromagnetic Interference (EMI) Shielding: ta-C coatings can act as EMI shields, blocking unwanted electromagnetic waves and protecting sensitive electronic components from interference.

7.Anti-Reflective Coatings: ta-C coatings are used to create anti-reflective surfaces in optical components, reducing light reflection and improving optical performance.

8.Thin-Film Electrodes: ta-C coatings can serve as thin-film electrodes in electronic devices, providing high electrical conductivity and electrochemical stability.

Overall, ta-C coating technology plays a significant role in the advancement of electronic devices, contributing to their improved performance, durability, and reliability.